The environment and sustainability are important factors in strategic company management. The expectations and questions of customers, consumers, media, investors and lenders are constantly growing. Society and business have concerns about climate change and CO2. Our industry can make significant contributions by focusing on our own topics such as recycling-friendly design or the use of recyclates.

The entire plastics packaging industry faces the task of positioning itself with regard to ecological and social issues. To this end, we conduct a constructive dialogue with relevant players from politics and society. In this process, we prepare position papers, environmental assessments and studies to demonstrate that our industry is aware of its responsibility – and that we are meeting it.

Sustainability of the plastics packaging industry

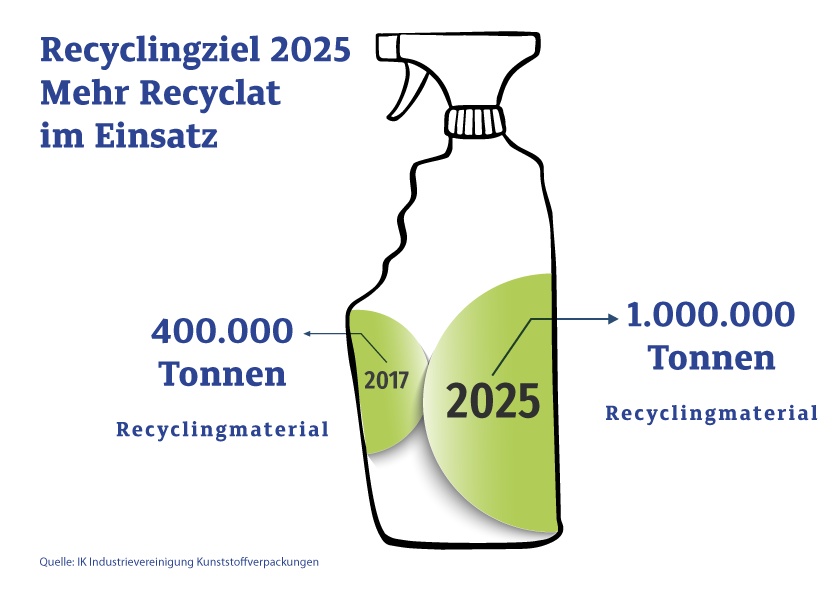

1 million tonnes of recycling material in production

In 2018, we – the German Association for Plastics Packaging and Films – set ourselves the ambitious target of strengthening the circular economy. The intention is to use at least one million tonnes of recycling material (or renewable raw materials) in the production of plastics packaging in Germany by 2025. In 2017, Germany manufacturers used 400,000 tonnes of recyclate (the technical term for recycling material used in manufacturing ) in the production of plastic packages.

With the significant increase in the use of recycling material we wish to send out a strong signal that Germany intends to reaffirm its leading role in Europe.

90 per cent recyclable or reusable household packaging

At least 90 per cent of household packaging is to be recyclable or reusable by 2025. This figure is already 75 per cent of plastic packages when measured in terms of their quantities in the “yellow sack” scheme and PET beverages container collection.

90 per cent is a realistic and also ecologically sound figure because a lot of packaged products are imported from abroad. Moreover, some modifications to packaging may have an overall negative impact in ecological terms.

By way of example, ultra-thin films with highly effective barrier layers provide sensitive food with very efficient protection. Recyclable alternatives require more material. However, there is potential in a number of areas for improving recyclability without compromising material efficiency. This is where we intend to concentrate our efforts.

Opinion Action Plan with ELIPSO

The European Green Deal and thus also the circular economy will be a decisive pillar of European policy in the coming years. The concrete measures to be expected from the political side in the field of the circular economy were outlined by the European Commission in its action plan of March 11, 2020. The IK Industrievereinigung Kunststoffverpackungen and the French partner association ELIPSO have closely scrutinized and evaluated the Commission’s announcements in relation to plastic packaging. The result is a joint declaration by the French and German plastics packaging industries.

Eco design

Insufficiently packaged materials have as great an impact on the environment as over-packaged goods. The golden rule is, therefore, to achieve the highest protective effect with as little packaging as possible. Eco design – designing for recycling – aims to minimise environmental pollution through packaging and the packaged goods over the entire product life cycle.

It is not just the visible characteristics of the packaging itself that are important in the eco design process – the system of goods logistics and waste disposal can also influence it. These aspects may often have a greater environmental impact than the design of the package itself.

As IK Industrievereinigung Kunststoffverpackungen e.V., we initiated the Eco Design Round Table. Its members cover the entire value chain. In 2019, the Round Table presented its “Management Guidelines for the Eco Design of Plastic Packaging”, which provides companies with practical assistance.

Bioplastics

With the “Green Deal”, the EU Commission presented its programme in 2019 to lead Europe into climate neutrality by 2050. Germany is already pursuing this goal by 2045, making it clear that plastics production must undergo a radical transformation. Regenerative raw material sources must gradually take the place of petroleum and other fossil raw material sources. In addition to recycled plastics, plastics obtained from biomass are also playing a growing role in this.

The IK has therefore set itself the goal of using at least one million tonnes of recycled or renewable raw materials in the production of new plastic packaging in Germany as early as 2025. In the IK working group Bioplastics, we deal with all questions concerning the topic of packaging and films made of bioplastics. Starting with the extraction and availability of raw materials, quality characteristics of bioplastics, areas of application, market development and recycling.

The Institute for Bioplastics and Bio Composites of Hanover University of Applied Sciences operates an information platform for bioplastics that gives free access to a large amount of numbers, facts, data and statistics about the global bioplastics market.

Our stance on the EU’s plastics strategy

With its plastics strategy published at the beginning of 2018, the EU Commission formulated and addressed its demands for the a circular economy of plastics packaging while also outlining measures aimed at promoting the circular economy and curbing littering.

We welcomed the strategy and expressed our position in some detail. The core elements of the far-reaching EU plastics strategy for the plastics packaging industry are recycling-friendly design and increasing the share of recyclates. Fighting global littering is also in the industry’s interest to ensure plastic products remain sustainable for the future.

Our members are making their contribution towards closing circular flows with their sustainability targets. We call on all players in the value chain to assist them in this.